New 3D-printed skin could end cosmetic testing on animals: Scientists

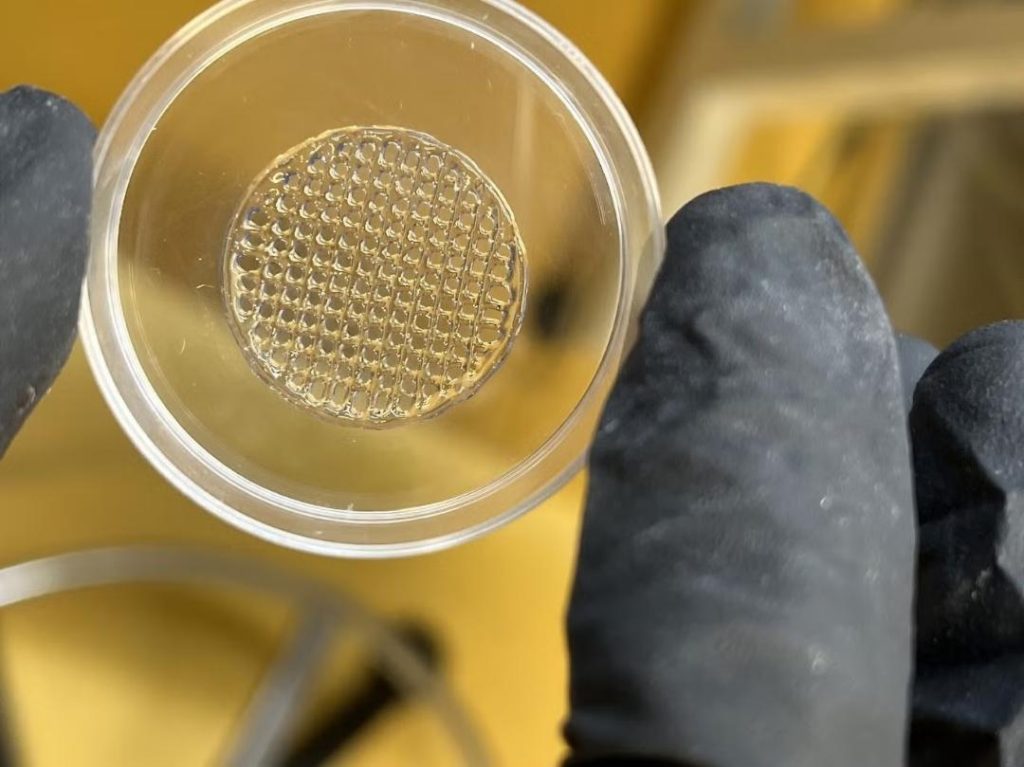

The cosmetics industry has long been criticized for its reliance on animal testing, with many arguing that it is inhumane and unnecessary. However, scientists may have just found a solution to this problem with the development of a 3D-printed human skin imitation containing living cells. According to a recent report, researchers from the Vellore Institute of Technology in India have created an artificial skin that replicates the natural three-layer structure of human tissue, making it an ideal substitute for animal testing.

The innovation, which was developed by a team of researchers led by Dr. S. Suresh, is a major breakthrough in the field of tissue engineering and could potentially eliminate the need for animal testing in the cosmetics industry. The artificial skin is made up of three layers, including the epidermis, dermis, and hypodermis, which are the same layers found in natural human skin.

The 3D-printed skin is made using a combination of living cells and a bio-ink, which is a special type of ink that is designed to promote cell growth and tissue regeneration. The cells are taken from human skin and are then mixed with the bio-ink to create a paste-like substance. This substance is then printed onto a substrate using a 3D printer, creating a layer of artificial skin.

Once the artificial skin is printed, it is left to mature for several days, allowing the cells to grow and spread throughout the tissue. After this period, the skin is ready for testing, and can be used to evaluate the safety and efficacy of cosmetic products, including creams, lotions, and nanoparticles.

The use of 3D-printed skin for cosmetic testing has several advantages over traditional animal testing methods. For one, it is much more accurate, as it mimics the natural structure and function of human skin. This means that it can provide more reliable results, which can help to reduce the number of failed products and reduce the risk of adverse reactions in humans.

Another advantage of 3D-printed skin is that it is much more cost-effective than animal testing. The cost of raising and caring for animals, as well as the cost of conducting the tests themselves, can be quite high. In contrast, the cost of creating a 3D-printed skin is relatively low, making it a more accessible option for companies.

In addition, the use of 3D-printed skin can help to reduce the number of animals that are used in testing. According to the Humane Society, over 500,000 animals are used in cosmetics testing each year, many of which are subjected to painful and inhumane procedures. By using 3D-printed skin, companies can reduce their reliance on animal testing and help to promote a more humane and compassionate industry.

The development of 3D-printed skin is not limited to the cosmetics industry. The technology has the potential to be used in a wide range of fields, including pharmaceuticals, biotechnology, and medicine. For example, 3D-printed skin could be used to test the safety and efficacy of new medicines, or to create artificial skin for use in wound healing and tissue engineering applications.

The researchers who developed the 3D-printed skin are now working to perfect the technology, including improving its scalability and reducing its cost. They are also working to establish a network of 3D-printed skin testing facilities around the world, which will make it easier for companies to access the technology and use it for their testing needs.

In conclusion, the development of 3D-printed skin is a major breakthrough in the field of tissue engineering and could potentially eliminate the need for animal testing in the cosmetics industry. The artificial skin is made up of living cells and replicates the natural three-layer structure of human tissue, making it an ideal substitute for animal testing. The use of 3D-printed skin has several advantages over traditional animal testing methods, including its accuracy, cost-effectiveness, and ability to reduce the number of animals used in testing.